Industrial Painting Services

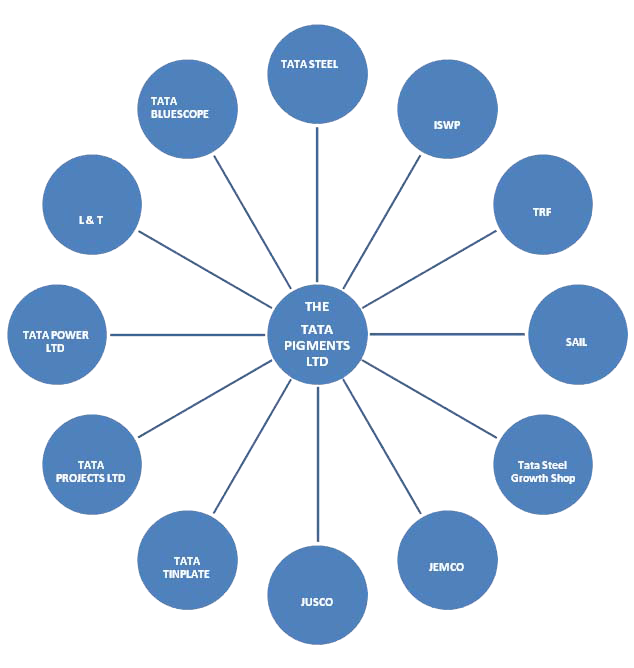

Earlier known as Apply and Supply Services this division came into existence in the year 2008. Later it was renamed as IDCS, which stands for Industrial & Decorative Coating Services.

The sole objective for formation of this division is “the protection of Steel & Civil Structures from corrosion.”

IDCS Style of Working

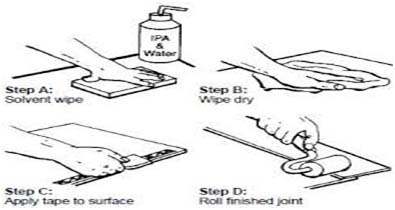

SSPC-SP-1

Solvent Cleaning - Removal of all detrimental foreign matter such as oil, grease, dirt, soil, salts, drawing and cutting compounds, and other contaminants from steel surfaces by the use of solvents, emulsions, cleaning compounds, steam or other similar materials and methods which involve a solvent or cleaning action.

SSPC-SP-2

St 2

Hand Tool Cleaning - Removal of all rust scale, mill scale, loose rust and loose paint to the degree specified by hand wire brushing, hand sanding, hand scraping, hand chipping or other hand impact tods or by a combination of these methods. The substrate should have a faint metallic sheen and also be free of oil, grease, dust, soil, salts and other contaminants.

SSPC-SP-3

St 3

Power Tool Cleaning - Removal of all rust scale, mill scale, loose paint, and loose rust to the degree specified by power wire brushes, power impact tools, power grinders, power sanders or by a combination of these methods. The substrate should have a pronounced metallic sheen and also be free of oil, grease, dirt, soil, salts and other contaminants. Surface should not be buffed or polished smooth.

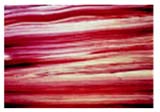

SSPC-SP-10

Sa-2-1/2

NACE 2

Near-White Blast Cleaning - Removal of nearly all mill scale, rust, rust scale, paint, or foreign matter by the use of abrasives propelled through nozzles or by centrifugal wheels, to the degree hereafter specified. A Near-White Blast Cleaned Surface Finish is defined as one from which all oil, grease, dirt, mill scale, rust, corrosion products, oxides, paint or other foreign matter have been completely removed from the surface except for very light shadows, very slight streaks or slight discolorations caused by rust stain, mill scale oxides, or light, tight residues of paint or coating that may remain. At least 95 percent of each square inch of surface area shall be free of all visible residues, and the remainder shall be limited to the light discoloration mentioned above.

Mechanized Painting

Fig. Airless Painting Machines

Fig. Airless Painting Machines

Spray coating is the process of coating an object with a liquid spray of paint or other fluid. Airless spray coating technology uses a spray produced by forcing a fluid under high pressure 500-5000 psi (34-340 bar) through a small nozzle (spray tip) to atomize the fluid. The fluid emerges as a narrow sheet at a high speed. The friction between the fluid and the air disrupts the sheet, breaking it into fragments initially and ultimately into droplets.

Fig. Roller for painting

Rollers can maintain a constant painting contrast and density. For this rollers are widely used for painting walls and floors. It is mostly chosen for industrial and professional works. But it’s important to choose the appropriate fabric of the roller as there are variations; For example, for rough surfaces long pile, foam for plain surface, semi pile for medium rough surface etc. Paint rollers give extremely thinner layer and totally smoother after drying. Paints using rollers are seen to be much more absorbed than brush or sprayer. There are also thrill rollers of small length which can be used for short width painting and finishing touch up.

Working at height

Fig. Painting Done by using Scaffolding, LD#1

Fig. Painting Done by using Scaffolding, LD#1

Fig. Man Lifter Used for Painting

Fig. Man Lifter Used for Painting

Fig. Use of Rope Access

Fig. Use of Rope Access

Fig. Mass Safety Meeting

Inspection and Testings

Site safety

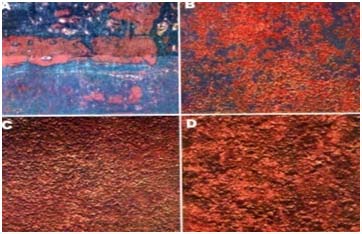

Identification of grade of corrosion in the structure as per ISO.

The performance and durability of any paint coating are significantly affected by the surface preparation carried out. This is even more important in the case of steel structures, where the selection of the method of surface preparation is crucial in any corrosion treatment. Different types of surface preparation can be selected depending upon the condition of the substrate, the paint system selected, the exposure and required durability of the coating, economic and environmental considerations etc. Below we outline some of the more common methods used on carbon steel with or without coating, galvanized steel, aluminium and light alloys, namely, dry blast cleaning, hand and power tool cleaning, water jetting, decreasing. The practical performance of the paint coatings is significantly affected by the condition of the surface prior to painting. The main relevant factors are:

Surface profile ISO 8501 provides a method of making a visual assessment of the cleanliness of surfaces and is commonly used to determine paint systems. This standard is divided into 4 parts.

Steel surface largely covered with adhering mill scale but little, if any, rust.

Steel surface which has begun to rust and from which the mill scale has begun to flake.

Steel surface on which the mill scale has rusted away or from which it can be scraped, but with slight pitting visible under normal vision.

Steel surface on which the mill scale has rusted away and on which general pitting is visible under normal vision.

Fig. Grades of Corrosion

Fig. Grades of Corrosion

Nature of Work

With the sole objective of “protection of steel & civil structure from corrosion”, here are some pictorial presentation of the jobs carried out by us as per our customer requirement.

5.1) Structural Painting

Continuing with the objective of protection against corrosion, we stand for Coatings solutions against corossion for past 7 years. With our excellent team we comply to the various requirements as given by the customer.

Fig. Representing Structural Painting

Fig. Representing Structural Painting

5.2) Plant Maintenance

With the sole objective for formation of this division is “the protection of Steel & Civil Structures from corrosion”, our journey started in the year 2008 in TATA STEEL, JSR as a major customer. Since then we have progressively grown with our objective of protection against corrosion.

We also offer a cost efficient flooring solution. Floor coatings helps to create an easy to clean, seamless surface. Results in hard wearing and durable surface, looks attractive and surface becomes chemically resistant. Improves safety as high gloss raises the brightness level by 300%.

Fig. Floor Coating

Fig. Floor Coating

5.4) Equipment Painting

Fig. Equipment Painting

Fig. Equipment Painting

5.5) Civil Painting

The company has extended its painting services to the civil section as well. With the availability of all kinds of resources we are able to dynamically apply our coatings in most of the jobs handed over to us.

Fig. Civil Painting

Fig. Civil Painting

About Wonders

TECHNICAL PRODUCT GUIDE OF SOLVENT BASED PAINT

|

SL. NO |

PRODUCT DESCRIPTION |

TECHNICAL KNOW-HOW |

METHOD OF APPLICATION |

CHEMICAL RESISTANCE GUIDE |

||||||||||||||||||

|

1 |

GP RED OXIDE PRIMER No of shades:-1 · Red |

MATT FINISH

DRYING 1 Hr.

FLASH POINT ABOVE 30?C

SOLID 55 -60 %

WET OPACITY 106 Sq Mt

WEIGHT IN KG /10 Lts : 13.5 KG |

BRUSH/ AIRLESS SPRAY

NOTES ONAIRLESS SPRAY: TIP RANGE: 31-37 THOU. TOTAL OUTPUT FLUID PRESSURE : 2500-3200 PSI(176-225 KG/SQ CM) POT LIFE : 2 – 3 HOURS THINNER : |

EXPOSURE |

SPLASH & SPILLAGE |

FUMES & OUTDOOR EXPOSURE |

||||||||||||||||

|

ACIDS |

Good |

Good |

||||||||||||||||||||

|

ALKALIS |

Very good |

Very good |

||||||||||||||||||||

|

SOLVENTS |

Good |

Good |

||||||||||||||||||||

|

SALT |

Excellent |

Good |

||||||||||||||||||||

|

WATER |

Excellent |

Excellent |

||||||||||||||||||||

|

2 |

H.B ZINC PHOSPHATE

No of shades:-2 · Grey · Red |

MATT FINISH

SOLID 65 -70 %

WEIGHT IN KG /10 Lts : 13.5 KG

COVERAGE AT DFT 75µ 6.8 M2 Lt

|

BRUSH/ AIRLESS SPRAY

NOTES ONAIRLESS SPRAY: TIP RANGE: 31-37 THOU. TOTAL OUTPUT FLUID PRESSURE : 2500-3200 PSI(176-225 KG/SQ CM) POT LIFE : 2 – 3 HOURS THINNER : |

CHEMICAL RESISTANCE GUIDE |

||||||||||||||||||

|

EXPOSURE |

SPLASH & SPILLAGE |

FUMES & OUTDOOR EXPOSURE |

||||||||||||||||||||

|

ACIDS |

Good |

Good |

||||||||||||||||||||

|

ALKALIS |

Very good |

Very good |

||||||||||||||||||||

|

SOLVENTS |

Good |

Good |

||||||||||||||||||||

|

SALT |

Good |

Good |

||||||||||||||||||||

|

WATER |

Excellent |

Excellent |

||||||||||||||||||||

|

3 |

G.P ALIMINIUM PAINT

|

LUSTRUS FINISH

NO WATER CONTENT

FLASH POINT ABOVE 30?C

WEIGHT IN KG /10 Lts : 9.2 KG

|

BRUSH/ AIRLESS SPRAY

NOTES ONAIRLESS SPRAY: TIP RANGE: 31-37 THOU. TOTAL OUTPUT FLUID PRESSURE : 2500-3200 PSI(176-225 KG/SQ CM) POT LIFE : 2 – 3 HOURS THINNER :: |

CHEMICAL RESISTANCE GUIDE |

||||||||||||||||||

|

EXPOSURE |

SPLASH & SPILLAGE |

FUMES & OUTDOOR EXPOSURE |

||||||||||||||||||||

|

ACIDS |

Very good |

Very good |

||||||||||||||||||||

|

ALKALIS |

Very good |

Very good |

||||||||||||||||||||

|

SOLVENTS |

Good |

Good |

||||||||||||||||||||

|

SALT |

Excellent |

Excellent |

||||||||||||||||||||

|

WATER |

Excellent |

Excellent |

||||||||||||||||||||

|

4 |

SYNTHETIC ENAMEL PAINT

No of shades:- 39 · White · Off white · Light Cream · Raw silk · Royal Ivory · Mid buff · Golden brown · Leaf brown · Brown · Pista · Mint green · Buzz green · Bottle green · Brilliant Green · Lemon Yellow · Golden Yellow · Canary Yellow · Black · Grey white · Light Grey · Sea Green · Pale Rose · Smoke grey · Dawn Glow · DA Grey · Deep Orange · Signal Red · Petal · PO Red · Candy · Crimson · Wild Lilac · Wild Purple · Satin blue · Sky Blue · Phiroza Blue · French Blue · Oxford Blue · Dawn |

GLOSSY FINISH

HIGH FLASH POINT ABOVE 30?C

SOLID 42 – 45 %

WEIGHT IN KG / 10 Lts : 9.5 KG

FINESS OF GRIND 7

|

BRUSH/ AIRLESS SPRAY

NOTES ONAIRLESS SPRAY: TIP RANGE: 31-37 THOU. TOTAL OUTPUT FLUID PRESSURE : 2500-3200 PSI(176-225 KG/SQ CM) POT LIFE : 2 – 3 HOURS

|

EXPOSURE |

SPLASH & SPILLAGE |

FUMES & OUTDOOR EXPOSURE |

||||||||||||||||

|

ACIDS |

Good |

Good |

||||||||||||||||||||

|

ALKALIS |

Very good |

Very good |

||||||||||||||||||||

|

SOLVENTS |

Good |

Good |

||||||||||||||||||||

|

SALT |

Good |

Good |

||||||||||||||||||||

|

WATER |

Excellent |

Excellent |

||||||||||||||||||||

|

5 |

P.U PAINT No of shades:- 21 · Brown · Lemon Yellow · Golden Yellow · Smoke Grey · Deep Orange · Signal Red · Wild Lilac · Phiroza Blue · Headland · Wind spray · Canary Yellow · PO Red · Aircraft Grey · Brilliant Green · Brilliant white · Light BS grey · Jet Black · Grey White · Ultramarine Blue · DA Grey · Pastel Green |

GLOSSY FINISH

WEIGHT IN KG /10 Lts : 10.5 KG

COVERAGE 14M2 Lt

SOLID 45 – 50 %

FINESS OF GRIND 7

|

BRUSH/ AIRLESS SPRAY

NOTES ONAIRLESS SPRAY: TIP RANGE: 31-37 THOU. TOTAL OUTPUT FLUID PRESSURE : 2500-3200 PSI(176-225 KG/SQ CM) POT LIFE : 2 – 3 HOURS

|

CHEMICAL RESISTANCE GUIDE |

||||||||||||||||||

|

EXPOSURE |

SPLASH & SPILLAGE |

FUMES & OUTDOOR EXPOSURE |

||||||||||||||||||||

|

ACIDS |

Good |

Good |

||||||||||||||||||||

|

ALKALIS |

Good |

Good |

||||||||||||||||||||

|

SOLVENTS |

Good |

Good |

||||||||||||||||||||

|

SALT |

Good |

Good |

||||||||||||||||||||

|

WATER |

Excellent |

Excellent |

||||||||||||||||||||

|

6 |

H.B EPOXY ZINC PHOSPHATE MIO No of shades:- 2 · Red · Grey

|

MATT FINISH

QUICK DRY

COVERAGE 7 M2 Lt

SOLID 65 – 68 %

SPECIFIC GRAVITY 1.26

|

BRUSH/ AIRLESS SPRAY

NOTES ONAIRLESS SPRAY: TIP RANGE: 31-37 THOU. TOTAL OUTPUT FLUID PRESSURE : 2500-3200 PSI(176-225 KG/SQ CM) POT LIFE : 2 – 3 HOURS |

CHEMICAL RESISTANCE GUIDE |

||||||||||||||||||

|

EXPOSURE |

SPLASH & SPILLAGE |

FUMES & OUTDOOR EXPOSURE |

||||||||||||||||||||

|

ACIDS |

Very good |

Very good |

||||||||||||||||||||

|

ALKALIS |

Very good |

Very good |

||||||||||||||||||||

|

SOLVENTS |

Good |

Good |

||||||||||||||||||||

|

SALT |

Good |

Excellent |

||||||||||||||||||||

|

WATER |

Excellent |

Excellent |

||||||||||||||||||||

|

7 |

H.B EPOXY COAL TAR

· Black |

SEMI GLOSSY

COVERAGE 6 M2 Lt

SOLID 65 – 70 %

WEIGHT IN KG /10 Lts : 11.5 KG |

BRUSH/ AIRLESS SPRAY

NOTES ONAIRLESS SPRAY: TIP RANGE: 31-37 THOU. TOTAL OUTPUT FLUID PRESSURE : 2500-3200 PSI(176-225 KG/SQ CM) POT LIFE : 2 – 3 HOURS |

EXPOSURE |

SPLASH & SPILLAGE |

FUMES & OUTDOOR EXPOSURE |

||||||||||||||||

|

ACIDS |

Good |

Good |

||||||||||||||||||||

|

ALKALIS |

Very good |

Very good |

||||||||||||||||||||

|

SOLVENTS |

Good |

Good |

||||||||||||||||||||

|

SALT |

Excellent |

Excellent |

||||||||||||||||||||

|

WATER |

Excellent |

Excellent |

||||||||||||||||||||

|

8 |

SINGLE PACK EPOXY PRIMER

· Grey |

EGG SHELLFINISH

QUICK DRYING

WEIGHT IN KG /10 Lts : 12.5 KG

COVERAGE AT 40 Microns 9 M2 Lt

SOLID 60 -66 %

FINESS OF GRIND 5.5 |

BRUSH/ AIRLESS SPRAY

NOTES ONAIRLESS SPRAY: TIP RANGE: 31-37 THOU. TOTAL OUTPUT FLUID PRESSURE : 2500-3200 PSI(176-225 KG/SQ CM) POT LIFE : 2 – 3 HOURS

|

CHEMICAL RESISTANCE GUIDE |

||||||||||||||||||

|

EXPOSURE |

SPLASH & SPILLAGE |

FUMES & OUTDOOR EXPOSURE |

||||||||||||||||||||

|

ACIDS |

Good |

Good |

||||||||||||||||||||

|

ALKALIS |

Very good |

Very good |

||||||||||||||||||||

|

SOLVENTS |

Good |

Good |

||||||||||||||||||||

|

SALT |

Good |

Excellent |

||||||||||||||||||||

|

WATER |

Excellent |

Excellent |

||||||||||||||||||||

|

9 |

H.R ALUMINIUM PAINT |

LUSTROUS FINISH

HEAT RESISTANT UP TO 450 ? C

WEIGHT IN KG /10 Lts : 10 KG

HIGH FLASH POINT ABOVE 30?C

|

BRUSH/ AIRLESS SPRAY

NOTES ONAIRLESS SPRAY: TIP RANGE: 31-37 THOU. TOTAL OUTPUT FLUID PRESSURE : 2500-3200 PSI(176-225 KG/SQ CM) POT LIFE : 2 – 3 HOURS |

CHEMICAL RESISTANCE GUIDE |

||||||||||||||||||

|

EXPOSURE |

SPLASH & SPILLAGE |

FUMES & OUTDOOR EXPOSURE |

||||||||||||||||||||

|

ACIDS |

Very good |

Very good |

||||||||||||||||||||

|

ALKALIS |

Very good |

Very good |

||||||||||||||||||||

|

SOLVENTS |

Good |

Good |

||||||||||||||||||||

|

SALT |

Good |

Good |

||||||||||||||||||||

|

WATER |

Excellent |

Excellent |

||||||||||||||||||||

|

10 |

ETCH PRIMER |

EGG SHELL TO MATT FINISH

QUICK DRYING

HIGH FLASH POINT ABOVE 30?C

HIGH COVERAGE

RUST PROOF

|

BRUSH/ AIRLESS SPRAY

NOTES ONAIRLESS SPRAY: TIP RANGE: 31-37 THOU. TOTAL OUTPUT FLUID PRESSURE : 2500-3200 PSI(176-225 KG/SQ CM) POT LIFE : 2 – 3 HOURS |

EXPOSURE |

SPLASH & SPILLAGE |

FUMES & OUTDOOR EXPOSURE |

||||||||||||||||

|

ACIDS |

Good |

Good |

||||||||||||||||||||

|

ALKALIS |

Very good |

Very good |

||||||||||||||||||||

|

SOLVENTS |

Good |

Good |

||||||||||||||||||||

|

SALT |

Good |

Good |

||||||||||||||||||||

|

WATER |

Excellent |

Excellent |

||||||||||||||||||||

|

11 |

BITUMINOUS BLACK |

GLOSS FINISH

HIGH FLASH POINT ABOVE 30?C

SOLID 45 -55 %

WEIGHT IN KG /10 Lts : 9 KG

|

BRUSH/ AIRLESS SPRAY

NOTES ONAIRLESS SPRAY: TIP RANGE: 31-37 THOU. TOTAL OUTPUT FLUID PRESSURE : 2500-3200 PSI(176-225 KG/SQ CM) POT LIFE : 2 – 3 HOURS |

CHEMICAL RESISTANCE GUIDE |

||||||||||||||||||

|

EXPOSURE |

SPLASH & SPILLAGE |

FUMES & OUTDOOR EXPOSURE |

||||||||||||||||||||

|

ACIDS |

Good |

Good |

||||||||||||||||||||

|

ALKALIS |

Very good |

Very good |

||||||||||||||||||||

|

SOLVENTS |

Good |

Good |

||||||||||||||||||||

|

SALT |

Good |

Good |

||||||||||||||||||||

|

WATER |

Excellent |

Excellent |

||||||||||||||||||||

|

12 |

ZINC RICH PRIMER |

SEMI MATT FINISH

WEIGHT IN KG /10 Lts : 15 KG

SOLID 55 -58 %

COVERAGE AT 75 Microns 7.5 M2 Lt ZINC % ON FILM 50

|

BRUSH/ AIRLESS SPRAY

NOTES ONAIRLESS SPRAY: TIP RANGE: 31-37 THOU. TOTAL OUTPUT FLUID PRESSURE : 2500-3200 PSI(176-225 KG/SQ CM) POT LIFE : 2 – 3 HOURS |

CHEMICAL RESISTANCE GUIDE |

||||||||||||||||||

|

EXPOSURE |

SPLASH & SPILLAGE |

FUMES & OUTDOOR EXPOSURE |

||||||||||||||||||||

|

ACIDS |

Good |

Good |

||||||||||||||||||||

|

ALKALIS |

Very good |

Very good |

||||||||||||||||||||

|

SOLVENTS |

Good |

Good |

||||||||||||||||||||

|

SALT |

Good |

Good |

||||||||||||||||||||

|

WATER |

Excellent |

Excellent |

||||||||||||||||||||

|

12 |

PRIMER CEMENT /WOOD

· WHITE · PINK |

SEMI MATT FINISH

WEIGHT IN KG /10 Lts : 15 KG

SOLID 55 -58 %

COVERAGE AT 75 Microns 7.5 M2 Lt

ZINC % ON FILM 50

|

BRUSH/ AIRLESS SPRAY

NOTES ONAIRLESS SPRAY: TIP RANGE: 31-37 THOU. TOTAL OUTPUT FLUID PRESSURE : 2500-3200 PSI(176-225 KG/SQ CM) POT LIFE : 2 – 3 HOURS |

CHEMICAL RESISTANCE GUIDE |

||||||||||||||||||

|

EXPOSURE |

SPLASH & SPILLAGE |

FUMES & OUTDOOR EXPOSURE |

||||||||||||||||||||

|

ACIDS |

Good |

Good |

||||||||||||||||||||

|

ALKALIS |

Good |

Good |

||||||||||||||||||||

|

SOLVENTS |

Good |

Good |

||||||||||||||||||||

|

SALT |

Good |

Good |

||||||||||||||||||||

|

WATER |

Excellent |

Excellent |

||||||||||||||||||||

Coatings Defect

Common Defects During Paint Storage

|

Defects |

Causes |

Preventive Measures |

Remedial Methods |

|

Settling Settlement of pigment to the bottom and failure to re-disperse

|

• Insufficient stirring during storage • Storage for long duration or under excessively warm condition • Excessive dilution or dilution with unsuitable materials |

• Store as recommended by • manufacturer • Avoid direct sunlight and long storage • Dilute with appropriate thinners as recommended by manufacturer |

• Stir paint to a homogeneous consistency • Employ mechanical stirring for heavy settling • Move to appropriate storage conditions as recommended by manufacturer • Discard paint |

|

Skinning Formation of a layer of skin on the container.

|

• Use of non-airtight container • Poor formulation such as lack of anti-skinning agent • Storage under excessively warm condition |

• Use airtight container • Avoid unnecessary opening of can • Store as recommended by manufacturer |

• Remove the layer of skin and stir paint to homogeneous consistency |

|

• Inform manufacturer for poor formulation |

|||

|

• Move to appropriate storage conditions as recommended by Manufacturer |

|||

|

Gelling Decreasing viscosity caused by bacterial degradation of the protein binder or other thickening agents. This is often accompanied by an offensive odour.

|

• Use of contaminated tools and water/solvents • Mixing of different brands or types of paints |

• Use clean tools and water/solvents • Avoid mixing different brands or types of paints |

• Discard paint

|

Common Defects During Application, Drying and Curing

|

Defects |

Causes |

Preventive Measures |

Remedial Methods |

|

Bleeding Leaching out of the existing paint film

|

• Frequent brushing on the same spot • Use of incompatible coats or thinner |

• Use proper application method • Apply with appropriate coat and thinner in accordance with manufacturer’s recommendation |

• Allow drying before painting over with an appropriate “buffer” coat (refer to manufacturer’s recommendation) |

|

Running/ Sagging/ Curtaining Flowing or dripping of paint from upper vertical surface to the lower part forming a tear-like or wavy appearance

|

• Painting of excessively thick film layer at one time • Excessive dilution • Application of gloss paint on existing paints or surface without sanding

|

• Increase frequency of painting thin film • Lower dilution ratio even where operability is poor • Sand and clean receiving surface before application • Apply with appropriate coat in accordance to manufacturer’s recommendation |

• Remove paint film, sand, clean and re-paint as in “Preventive Measure” |

|

Wrinkling/ Rivelling Formation of undulating wrinkling film |

• Application of thick Oil-Alkyd, which causes shrinkage of paint film. This tends to occur when drying is expedited at high temperatures Apply with appropriate coat in accordance with manufacturer’s recommendation • Painting over insufficiently dried paint |

• Sand and clean receiving surface before application • Avoid painting in thick film • Avoid accumulation of paint around bolts, angles, etc. • Observe over coating intervals in accordance with manufacturer’s recommendation |

• Remove paint film, sand, clean and re-paint as in “Preventive Measure” |

|

Crawling Slipping or inability to form a film.

|

• Painting over surfaces that are not prepared, e.g. sand, dirt and dust on the surface

|

• Sand and clean receiving surface before application • Apply with appropriate coat in accordance with manufacturer’s recommendation |

• Remove paint film, sand, clean and re-paint as in “Preventive Measure” |

|

Crating Formation of small bowl-shaped depressions

|

• Painting over surfaces that are not prepared, e.g. sand, dirt and dust on the surface • Use of contaminated tools and water /solvents

|

• Sand and clean receiving surface before application • Apply with appropriate coat as recommended by manufacturer • Use clean tools and water/solvents |

• Remove paint film, sand, clean and re-paint as in “Preventive Measure” |

|

Lifting Attacking by successive coating on existing paint

|

• Use of incompatible coats, which cause shrinkage of paint film or attacking of thinner on undercoat |

• Observe over coating intervals as recommended by manufacturer • Allow undercoating to dry before application of successive coating • Sand and clean receiving surface before application • Apply with appropriate coat as recommended by manufacturer |

• Remove paint film, sand, clean and re-paint as in “Preventive Measure” |

|

Prolonged Drying Time Inability to dry after application |

• Incorrect mixing • Use of defective paint |

• Mix as recommended by manufacturer • Discard paint if it is defective |

• Remove paint film, sand, clean and re-paint as in “Preventive measure” |

|

Loss of Gloss Reduction of lustre on drying caused by severe absorption of undercoat |

• Application on rough or unclean surfaces • Inadequate or excessive dilution • Use of unsuitable thinner • Application of excessively thin film • Result as blushing occur • Drying occurs in the presence of excessive moisture and pollutant |

• Increase frequency of painting in thin film • Paint adequate thickness of film • Use appropriate thinner as recommended by manufacturer • Avoid painting at high humidity • Prepare receiving surface and apply appropriate sealer |

• Remove paint film, sand, clean and re-paint as in “Preventive Measure”

|

Common Defects During Service Life

|

Defects |

Causes |

Preventive Measures |

Remedial Methods |

|

Efflorescence a) Migration of alkaline from cement based materials and crystallisation on the surface as salts

|

• Painting over insufficiently cured plaster/concrete |

• Paint on receiving surface with moisture content not exceeding 6% (or refer to manufacturer’s recommendation |

• Remove efflorescence, unstable matters and loose paint film • Repaint on receiving surface with moisture content not exceeding 6% (or refer to manufacturer’s recommendation) • Seal off with compatible alkali resisting primer before painting • In most persistent cases, epoxy-based paint has been used with good success but at a higher cost |

|

• Painting over substrate’s hairline cracks |

• Paint on substrate with cracks not visible at 1.5m away from walls |

• Patch cracks • Repaint on receiving surface with moisture content not exceeding 6% (or refer to manufacturer’s recommendation) |

|

• Water seepage through roof, toilets etc |

• Install proper waterproofing system before painting |

• Arrest moisture Source • Prepare and treat the surface • Repaint on receiving surface with moisture content not exceeding 6% (or refer to manufacturer’s recommendation) |

|

• Rise of dampness from ground |

• Install proper waterproofing system before painting |

• Treat dampness • Repaint on receiving surface with moisture content not exceeding 6% (or refer to manufacturer’s recommendation) |

|

b) Migration of inherent wood gum and resins in timber |

• Painting over insufficiently dried timber • Failure to use primer |

• Paint on receiving surface with moisture content not exceeding 15% (or refer to manufacturer’s recommendation) • Apply appropriate primer to seal the surface before painting with the undercoat and topcoat • Observe over coating intervals in accordance with manufacturer’s recommendations |

• Repaint on receiving surface with moisture content not exceeding 15% (or refer to manufacturer’s recommendation) • Apply appropriate primer to seal the surface before repainting with the undercoat and topcoat |

|

c) Discoloration of paintwork

on metals |

• Failure to remove unstable matter during surface preparation |

• Employ good surface preparation before painting |

• Clean surface thoroughly before repainting |

|

Deterioration / Erosion of Pigment

|

• Use of vibrant colours paint with organic particles that are easily susceptible to UV degradation • Use of paint with water sensitive pigments • Use of paint with low quality emulsions |

• Select colours that are more stable • Use appropriate coating system |

• Remove powder and unstable matter • Repaint with appropriate coating system • Select colours that are more stable |

|

Yellowing |

• Use of paint with certain ingredients, e.g. yellowing epoxy and alkyd resins, which are easily affected by light, heat or environmental contaminants |

• Use non-yellowing paints |

• Prepare surface and repaint with non- yellowing paints |

|

Saponification

|

• Use of alkyd-based paints on cement based materials. The alkalis from the cement attack the oil in the alkyd resin |

• Avoid using alkyd-based paints on cement based surfaces • Use appropriate coating system |

• Remove paint work and repaint with appropriate system |

|

Chalking Natural ageing of paint. The extent of chalking will depend on paint formulation and surface exposure to weather

|

• Use of non-weathering resistant paint |

• Use weather resistant paint for areas exposed to weather or UV |

• Prepare surface and repaint with appropriate system |

|

Peeling & Flaking Paint a) Moisture related

|

• Water seepage through roof, toilets etc |

• Install proper waterproofing system before painting |

• Arrest moisture Source • Prepare and treat the surface • Repaint on receiving surface with moisture content not exceeding 6% (or refer to manufacturer’s recommendation) |

|

• Painting over insufficiently cured plaster/ concrete |

• Paint on receiving surface with moisture content not exceeding 6% (or refer to manufacturer’s recommendation) |

• Remove efflorescence, unstable matters and loose paint film • Repaint on receiving surface with moisture content not exceeding 6% (or refer to manufacturer’s recommendation |

|

b) Incorrect Paint System

|

• Failure to use primer / sealer primer for non- ferrous metals • Failure to use etching • Use of poor alkali-resisting primer / undercoats or insufficient penetrative primer |

• Prime/seal all bare surfaces with appropriate primer or sealer |

• Remove all defective paint work and prepare the surface • Repaint with appropriate system |

|

c) Poor Surface Preparation

|

• Failure to remove unstable matter during surface preparation • Use of water-soluble putty/ poor adhering plaster

|

• Employ adequate surface preparation to remove all unstable matter • Surface must be clean, dry and stable before receiving paint |

• Remove all defective and loose paint film, and unstable matter such as plaster etc • Prime/seal the surface with appropriate primer/sealer to further stabilise the surface • Re-coat with appropriate coating system |

|

Blistering This is a moisture-related phenomenon. The amount of moisture and flexibility of the paint film determine the size of the blister

|

• Painting on a warm surface • Moisture migration through painted surface |

• Paint on receiving surface with moisture content not exceeding 6% (or refer to manufacturer’s recommendation) |

• Remove defective paint and prepare surface accordingly to receive paint • Repaint on receiving surface with moisture • content not exceeding 6% (or refer to manufacturer’s recommendation) |

|

Staining It should be noted that staining may be attributed to improper design of the building and its façade

|

• Use of details that traps and accumulates dirt. Streak marks are formed when dirt gets washed down along the sides of the painted vertical walls, especially on elastomeric coated wall. • Yellowish-brown stains caused by moisture • It can be an indication of waterproofing problem in other parts of the building |

• Avoid details and coatings that trap and attract dirt • Ensure all potential water leakage and condensation are in check |

• Remove defective paint and prepare surface accordingly to receive paint • Apply with more dirt-resistant paint system • Arrest moisture source. • Prepare and treat the surface • Repaint on receiving surface with moisture content not • exceeding 6% (or refer to manufacturer’s recommendation) • Repaint with appropriate system |

|

Rust Stains

|

• Corrosion of metal elements that are attached to, adjacent to or embedded in, another substrate • Installation of metal elements that are not treated |

• Protect and treat all metal parts from corrosion |

• Remove metal parts and treat the metal surface

• Clean the walls and prepare the surface to receive painting • Repaint with appropriate system |

|

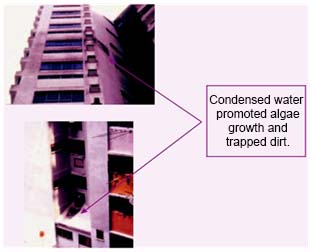

Algae & Fungi Growth • Temperature, humidity conditions and moisture content of the surfaces/ substrates would determine the likelihood of algae and fungi formation. • On buildings, algae are generally found outdoors such as external wall surfaces, as their chlorophyll characteristic requires sufficient sunlight for growth. Whilst fungi are commonly found on internal wall surfaces of damp areas such as bathrooms. • It should be noted that algae growth may be attributed to improper design of the building and its façade. |

• Moisture source and retention • Employing of details that assist growth of algae/ fungi: (i) Profile of substrates; rough-textured finishes or rough concrete surfaces

|

• Avoid details with very rough textures or rough-cast plastered finishes • Use a more algae resistant paint to delay the onset of algae growth • Use capping and copings • Employ overhanging roofs to protect the walls

Overhanging roof details |

• Remove dirt and algae by high-pressure water jetting • Treat infected areas with fungicidal wash • Re-paint with a more algae resistant paint

Overhanging roof |

|

OUTDOOR

|

INDOOR

|

|

|

|

(ii) Condensation-prone walls |

Capping details • Increase thickness of wall to provide more insulation so as to minimise the temperature difference • Paint on receiving surface with moisture content not exceeding 6% (or refer to manufacturer’s recommendation) • Incorporate insulating material in the concrete • Apply a coating of anti-condensation paint |

• Remove algae by high-pressure water jetting • Supplemented with manual scrubbing if necessary • Treat infected areas with fungicidal wash • Insulate with an anti-condensation coating • Re-paint with a more algae resistant paint • Divert condensed water from air-con outlets with trays and piping |

|

(iii) Concrete gutters & water-prone areas

|

• Ensure proper drainage • Avoid potential water retention • Use a more algae resistant paint • Ensure good workmanship |

• Remove dirt and algae by high-pressure water jetting • Treat infected areas with a fungicidal wash • Re-paint with a more algae resistant paint |

|

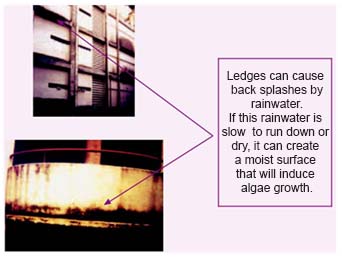

(iv) Ledges

|

• Ensure proper drainage • Avoid potential water retention • Use a more algae resistant paint • Ensure good workmanship |

• Remove dirt and algae by high-pressure water jetting • Treat infected areas with a fungicidal wash • Re-paint with a more algae resistant paint |

|

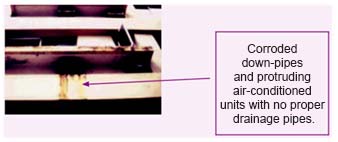

(v) Water drainage pipes and fittings

|

• Ensure proper drainage • Avoid potential water retention • Use a more algae resistant paint • Ensure good workmanship |

• Remove dirt and algae by high-pressure water jetting • Treat infected areas with a fungicidal wash • Rectify the water drainage problem • Re-paint with a more algae resistant paint |

|

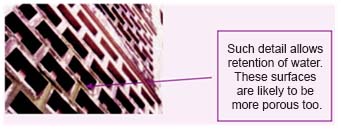

(vi) Precast Grille Vent |

• Avoid porous surfaces for areas exposed to weather • If necessary, seal or waterproof porous surfaces • Use a more algae resistant paint |

• Remove dirt and algae by high-pressure water jetting • Treat infected areas with a fungicidal wash • Seal and waterproof the surface • Re-paint with a more algae resistant paint to delay the onset of algae growth |

INDUSTRIAL USERS